SUPERNOVA

30k COTS

A Full Reimagining

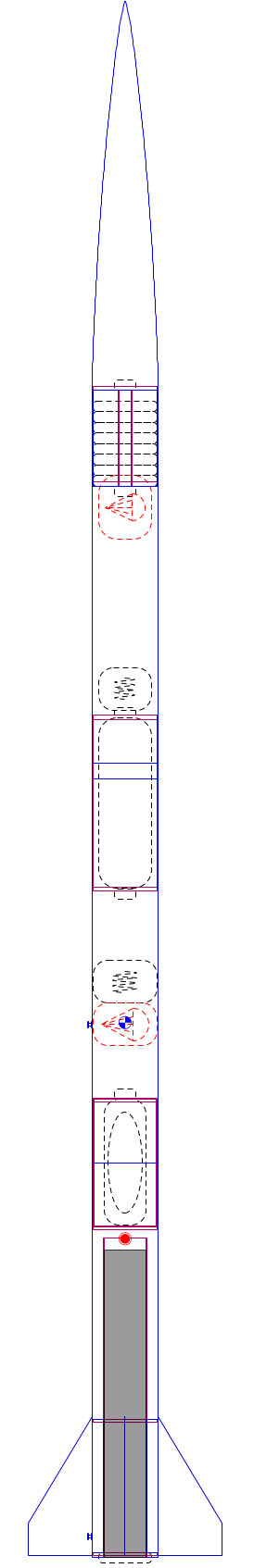

With the success of the past teams launches, pushing for new heights in the 30k category calls for a reimagining of the past years rocket designs. With changes every year, from the composite bulkheads after the first years recovery failure, to custom carbon tubing for weight saving after the second year weight issue. One thing that stands out on all three rockets is available space. When shooting for 30k this space is drastically reduced. The team has to optimize drag on the rocket calling for a smaller body tube along with shorter length. While making the rocket shorter, the rocket motor has to be stronger and therefor larger. This extra length also removes usable space for the team.

Apogee: 30,540ft

Max Velocity: Mach 2

Acceleration: 28G

Time to Apogee: 38s

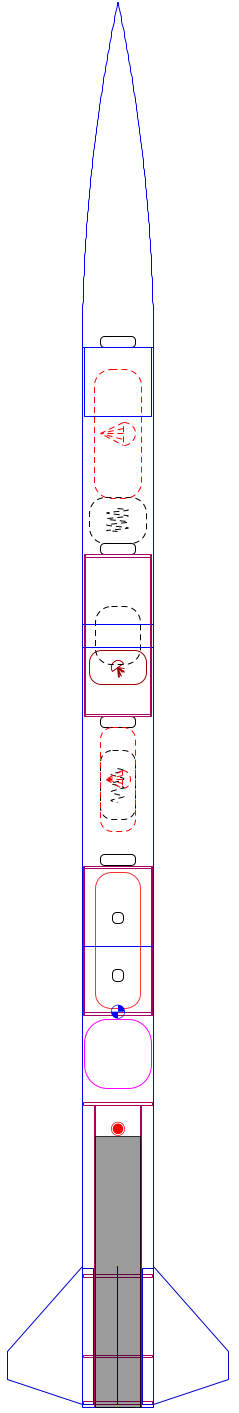

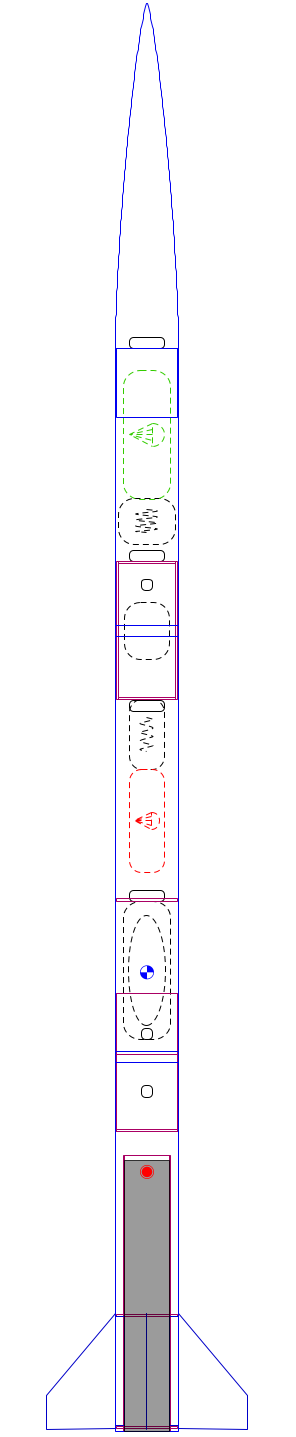

Peng-One

Peng-One.2

Arctic Arrow

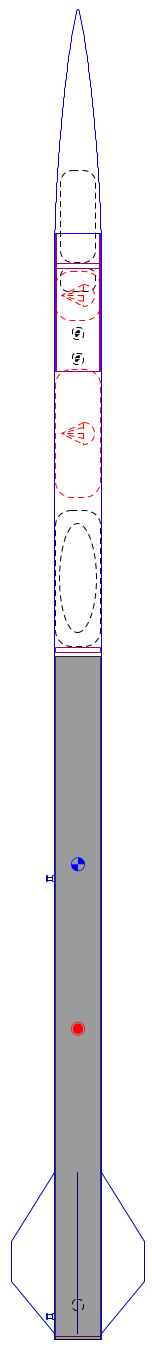

SUPERNOVA

Recovery

Due to the smaller available volume in the rocket, this years team is designing a tender release system that allows for both the main and drogue parachute to deploy at apogee with only the drogue fully opening and the main opening at the desired height. This allows for only a single connection point on the rocket, making the body tube one continuous piece. This single piece will be the longest custom wound tube to date for the club coming in slightly over 8ft long. The other large hurdle that the team has to overcome is the inability to use black powder for an ejection method due to the low concentration of oxygen at apogee. This years team will design a custom CO2 ejection system that is hosed with the avionics of the rocket to cause the separation needed for recovery.

Airframe

The team has opted to create their own custom carbon fiber body tube due to 2 reasons. The primary reason being the ability to get a custom length of tube, longer than those available commercially. This years rocket requires a continuous length of 8ft, which is 3 feet longer than the longest available to purchase. The second reason for creating a custom tube is the cost. The team is able to cut the cost down by over 300% when creating custom tubes as the material cost is much lower.